PET Bottle Water Washing Filling And Capping Machine

PET Bottle Water Washing Filling And Capping Machine is one of advanced models which is our company combines international advanced self-filling process and technology developed specifically for mineral water, pure water and other non-gas beverage filling installation.

5.0

like

Brand:

SKYM

Model:

16-16-8

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

PET Bottle Water Washing Filling And Capping Machine is one of advanced models which is our company combines international advanced self-filling process and technology developed specifically for mineral water, pure water and other non-gas beverage filling installation.

Size information

| Model | Washing | Filling | Capping | Capacity(b/h) | Motor | Overall |

| heads | heads | heads | 500ml | power | dimension(mm) | |

| (kw) | ||||||

| CGF14-12-5 | 14 | 12 | 5 | 2000-4000 | 1.5 | 2100*1400*2500 |

| CGF18-18-6 | 18 | 18 | 6 | 5000-7000 | 2.2 | 2460*1720*2650 |

| CGF24-24-8 | 24 | 24 | 8 | 8000-12000 | 3 | 3100*2100*2650 |

| CGF32-32-10 | 32 | 32 | 10 | 12000-15000 | 4 | 3500*2500*2650 |

| CGF40-40-10 | 40 | 40 | 10 | 16000-20000 | 7.5 | 4600*1800*2650 |

| CGF48-48-12 | 48 | 48 | 12 | 20000-24000 | 9.5 | 5200*4500*3400 |

| CGF50-50-15 | 50 | 50 | 15 | 24000-26000 | 11 | 5800*4500*3400 |

| CGF60-60-15 | 60 | 60 | 15 | 26000-30000 | 12 | 6500*4500*3400 |

| CGF72-72-18 | 72 | 72 | 18 | 30000-36000 | 14 | 6800*4500*3700 |

Main feature

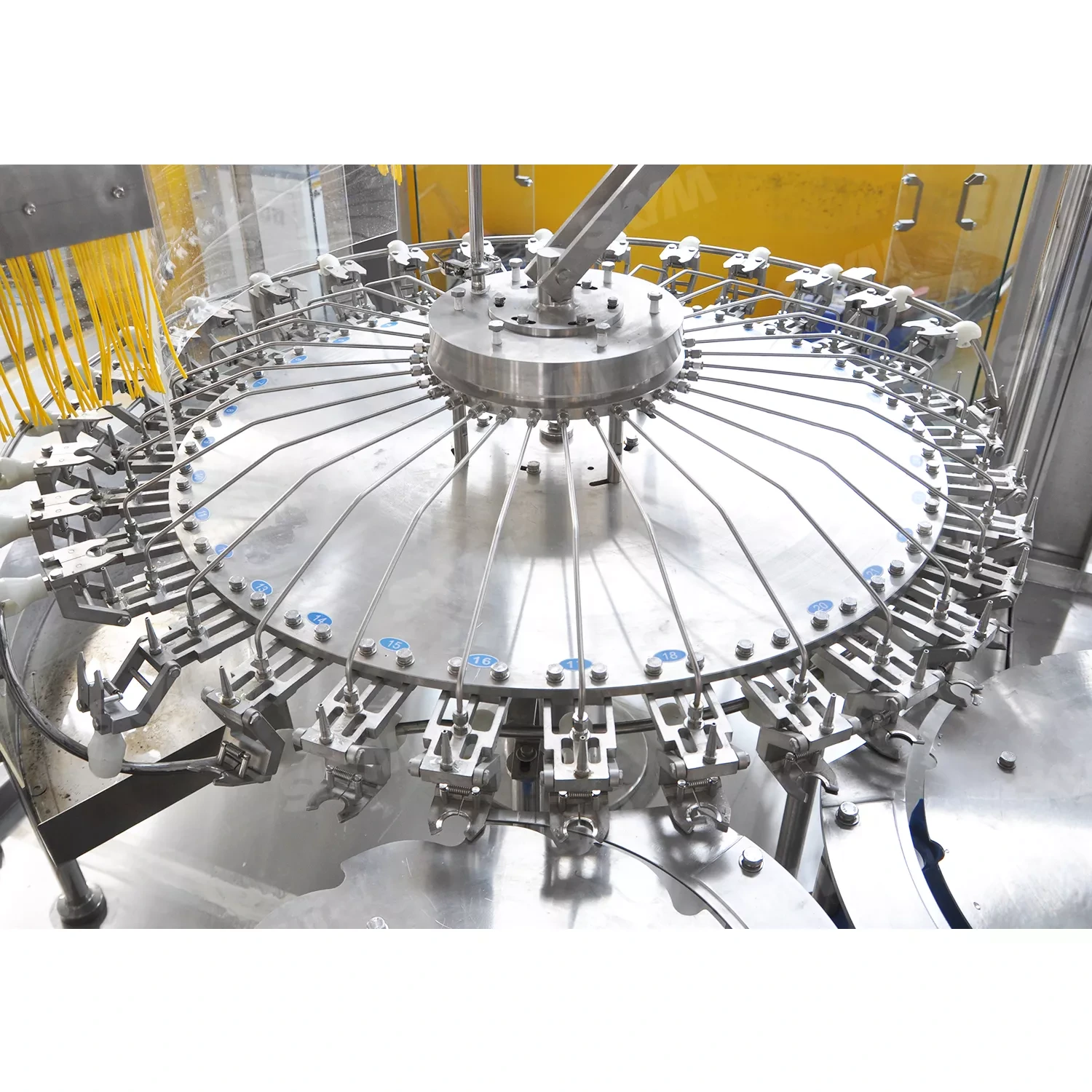

Characteristics of PET Bottle Water Washing Filling And Capping Machine :

1.Host adopt advanced PLC automatic control technology,the key electrical components from famous company such as Japan,France Schneider.

2.Using the wind sent access and move wheel in the bottle directly connected technology;Canceled screw and conveyor chains,this enable the change the bottle-shaped become easier.

3.Bottles transmission adopt clip bottleneck technology,bottle-shaped transform not need to adjust the equipment level,only change relater the curved plate,wheel and nylon parts is enough

4.High-speed large gravity flow valve filling valve,filling fast,filling accurate and no liquid lose.

5.The specially designed stainless steel bottle washing machine clip is solid and durable,no touch with the screw location of bottle mouth to avoid secondary pollution.

This is the products of our PET Bottle Water Washing Filling And Capping Machine.

FQA

1.How can i know the machinery quality before i order?

First,we will invite you visiting our factory to check the machines quality,and show the machines running for you in our factory.

2.How can i know the machinery quality before i order?

First,we will invite you visiting our factory to check the machines quality,and show the machines running for you in our factory

3.Are all machinery your factory made?

Our factory make the water purification and filling packing plants.we do not make the bottle making machinery,we have good quality bottle making machinery partner,and we provide to customer same long warranty time and good after service.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Related Products

no data

no data