| Availability: | |

|---|---|

| Quantity: | |

GF24-4

SKYM

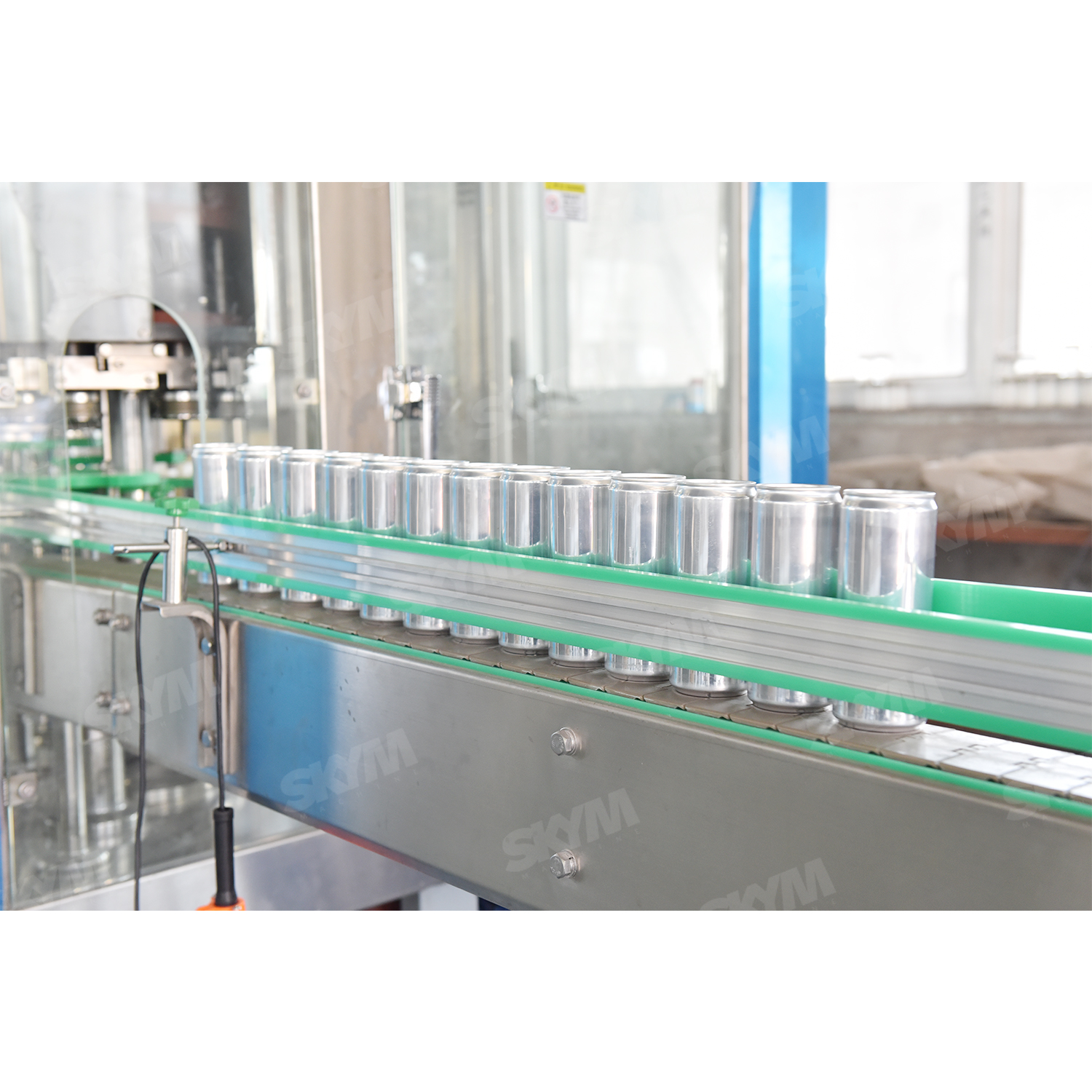

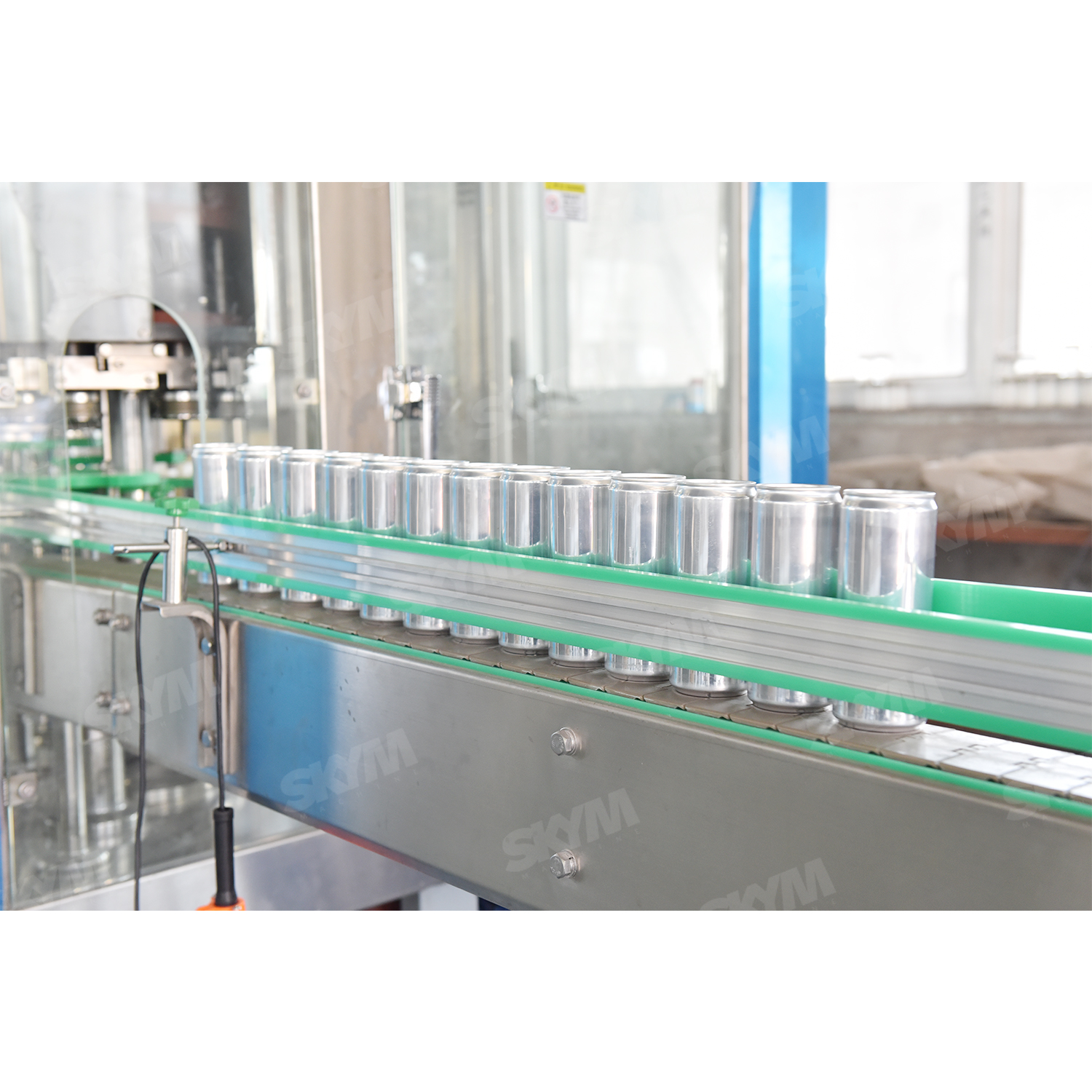

3 in 1 10000cans/hr Aluminum Can Filling Machine is a new generation tinplate pop can seaming machine (sealing machine) designed and manufactured by our company through referring to the most advanced same products in the world according to the actual situation in domestic food, canning factories and beverage plants.

Main Technical Data

| Model | GF 18-4 | GF 24-4 | GF 30-5 | GF48-6 | GF 56-6 |

| Carbonated Drink | 6000cans/hr | 10000cans/hr | 12000cans/hr | 18000cans/hr | 24000cans/hr |

| Juice | 12000cans/hr | 15000cans/hr | 18000cans/hr | 24000cans/hr | 36000cans/hr |

The production adopts frequency conversion speed adjustment with touch screen operation. In addition, it is provided with such features as no cap feeding in case of no can, and alarm of cap shortage. The appearance design of full stainless steel materials fully complies with food and sanitation requirements. Furthermore, the steam jetting device and remote control system can be equipped according to customer requirements. It is currently one of the most advance seaming devices in the country.

It is applicable for equal pressure filler and capper of carbonated drinks in beer and coca cola ,pepsi drink and other carbonated drink production industry. It is a pop canned beer in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit. Filling and sealing is the overall designed, power system by filling sealing system to ensure that both the absolute synchronization and coordination. It adopts the advanced machine, electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip long-distance control system according to the customers' request. It is the preferred equipment for the medium beer and beverage plant.

when you send inquiry,please also included the capacity and can shape and volume you need to work on the machine, it is easy and accurately for us to recommand a right machine!

If any special,our manufacture also can design the machines according your requirement.

This is our products of 3 in 1 10000cans/hr Aluminum Can Filling Machine.

FAQ

1.Can your factory provide he whole plant from A to Z?

Yes, we can provide the complete plant, from bottling making plant,water purification plant,to filling packing plant.

2.Are all machinery your factory made?

Our factory make the water purification and filling packing plants.we do not make the bottle making machinery,we have good quality bottle making machinery partner,and we provide to customer same long warranty time and good after service.

3.How can i know the machinery quality before i order?

First,we will invite you visiting our factory to check the machines quality,and show the machines running for you in our factory.

4.What certificates you can provide?

Our factory provide the CE,SGS,ISO,and according to some countries,we also can provide the PVOC, COC,SONCAP...etc.

3 in 1 10000cans/hr Aluminum Can Filling Machine is a new generation tinplate pop can seaming machine (sealing machine) designed and manufactured by our company through referring to the most advanced same products in the world according to the actual situation in domestic food, canning factories and beverage plants.

Main Technical Data

| Model | GF 18-4 | GF 24-4 | GF 30-5 | GF48-6 | GF 56-6 |

| Carbonated Drink | 6000cans/hr | 10000cans/hr | 12000cans/hr | 18000cans/hr | 24000cans/hr |

| Juice | 12000cans/hr | 15000cans/hr | 18000cans/hr | 24000cans/hr | 36000cans/hr |

The production adopts frequency conversion speed adjustment with touch screen operation. In addition, it is provided with such features as no cap feeding in case of no can, and alarm of cap shortage. The appearance design of full stainless steel materials fully complies with food and sanitation requirements. Furthermore, the steam jetting device and remote control system can be equipped according to customer requirements. It is currently one of the most advance seaming devices in the country.

It is applicable for equal pressure filler and capper of carbonated drinks in beer and coca cola ,pepsi drink and other carbonated drink production industry. It is a pop canned beer in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit. Filling and sealing is the overall designed, power system by filling sealing system to ensure that both the absolute synchronization and coordination. It adopts the advanced machine, electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip long-distance control system according to the customers' request. It is the preferred equipment for the medium beer and beverage plant.

when you send inquiry,please also included the capacity and can shape and volume you need to work on the machine, it is easy and accurately for us to recommand a right machine!

If any special,our manufacture also can design the machines according your requirement.

This is our products of 3 in 1 10000cans/hr Aluminum Can Filling Machine.

FAQ

1.Can your factory provide he whole plant from A to Z?

Yes, we can provide the complete plant, from bottling making plant,water purification plant,to filling packing plant.

2.Are all machinery your factory made?

Our factory make the water purification and filling packing plants.we do not make the bottle making machinery,we have good quality bottle making machinery partner,and we provide to customer same long warranty time and good after service.

3.How can i know the machinery quality before i order?

First,we will invite you visiting our factory to check the machines quality,and show the machines running for you in our factory.

4.What certificates you can provide?

Our factory provide the CE,SGS,ISO,and according to some countries,we also can provide the PVOC, COC,SONCAP...etc.

content is empty!

Company Address:Leyu Town, Zhangjiagang City, Jiangsu Province, China, Post Code: 215626

Phone: 0086-15151503519

Tel: 0086-512-58905519

E-mail: info@sky-machine.com

WhatsApp: 0086-15151503519

Skype: jack.skymachine

Copyright © 2020 Zhangjiagang Sky Machine Co., LTD. Support by Leadong.com 苏ICP备20028770号-1